Types of Wood Glue for Chair Repair

.jpg)

The choice of wood glue significantly impacts the longevity and structural integrity of your chair repair. Selecting the right adhesive depends on the type of wood, the joint’s complexity, and the desired strength and working time. Understanding the properties of different glues is crucial for a successful and lasting repair.

Comparison of Wood Glues for Chair Repair, Best glue for chair joints

The following table compares four common wood glues suitable for chair repair, highlighting their strengths and weaknesses to aid in your selection. Consider factors like open time (the time the glue remains workable), clamping requirements, and drying time when making your decision. Remember that proper surface preparation is always paramount for optimal adhesion.

| Glue Type | Strengths | Weaknesses | Drying Time (approx.) | Ideal Applications |

|---|---|---|---|---|

| Polyvinyl Acetate (PVA) | Versatile, readily available, relatively inexpensive, water-cleanable, good for most wood types. | Lower strength than some other glues, susceptible to water damage if not properly sealed. | 30-60 minutes | General chair repairs, non-structural joints, simple repairs. |

| Aliphatic Resin Glue | Stronger than PVA, good water resistance, relatively fast drying time. | More expensive than PVA, requires careful clamping. | 20-40 minutes | Strong joints, structural repairs, mortise and tenon joints. |

| Epoxy Glue | Extremely strong, gap-filling capabilities, excellent water resistance. | More expensive, longer drying time, requires precise mixing, not easily cleaned up. | 2-24 hours (depending on type) | Broken chair legs, complex repairs, filling significant gaps. |

| Yellow Wood Glue | Strong, good gap-filling, relatively inexpensive, good for porous woods. | Can be slightly brittle if over-dried, less water-resistant than epoxy or aliphatic resin. | 30-60 minutes | General chair repairs, strong joints, filling small gaps. |

PVA, Aliphatic Resin, and Epoxy Glues: A Detailed Comparison

These three glue types represent a spectrum of strength and properties. PVA (Polyvinyl Acetate) glues are the most common and readily available, offering good strength for many chair repairs, but are less water-resistant than the other two. Aliphatic resin glues offer a significant increase in strength and water resistance, making them ideal for structural repairs. Epoxy glues are the strongest and most water-resistant, but require more precise application and have longer drying times. Their gap-filling capabilities are particularly useful for broken components.

Glue Properties: Viscosity, Open Time, and Clamping

Viscosity refers to the glue’s thickness or flow. PVA glues generally have a lower viscosity than aliphatic resin or epoxy glues, making them easier to spread thinly. Open time is the period the glue remains workable before setting. PVA glues typically have a longer open time than aliphatic resin glues, which in turn have a longer open time than epoxies. Clamping pressure and time are crucial for ensuring proper adhesion. Stronger glues, like epoxies and aliphatic resin glues, often require more clamping pressure and longer clamping times to achieve maximum bond strength. PVA glues usually require less clamping pressure. Always refer to the manufacturer’s instructions for specific recommendations regarding clamping pressure and time for each glue type.

Choosing the Right Glue for Different Chair Joint Types: Best Glue For Chair Joints

The success of a chair repair hinges significantly on selecting the appropriate adhesive for the specific joint type. Different joints experience varying stresses and require glues with different properties to ensure a lasting, strong repair. Understanding these nuances is crucial for achieving professional-quality results.

Glue Selection for Various Chair Joint Types

The table below Artikels recommended glue types for common chair joint types, considering their respective strengths and weaknesses. The choice often depends on the wood type, the joint’s complexity, and the desired level of strength and flexibility.

| Joint Type | Recommended Glue Type | Advantages | Considerations |

|---|---|---|---|

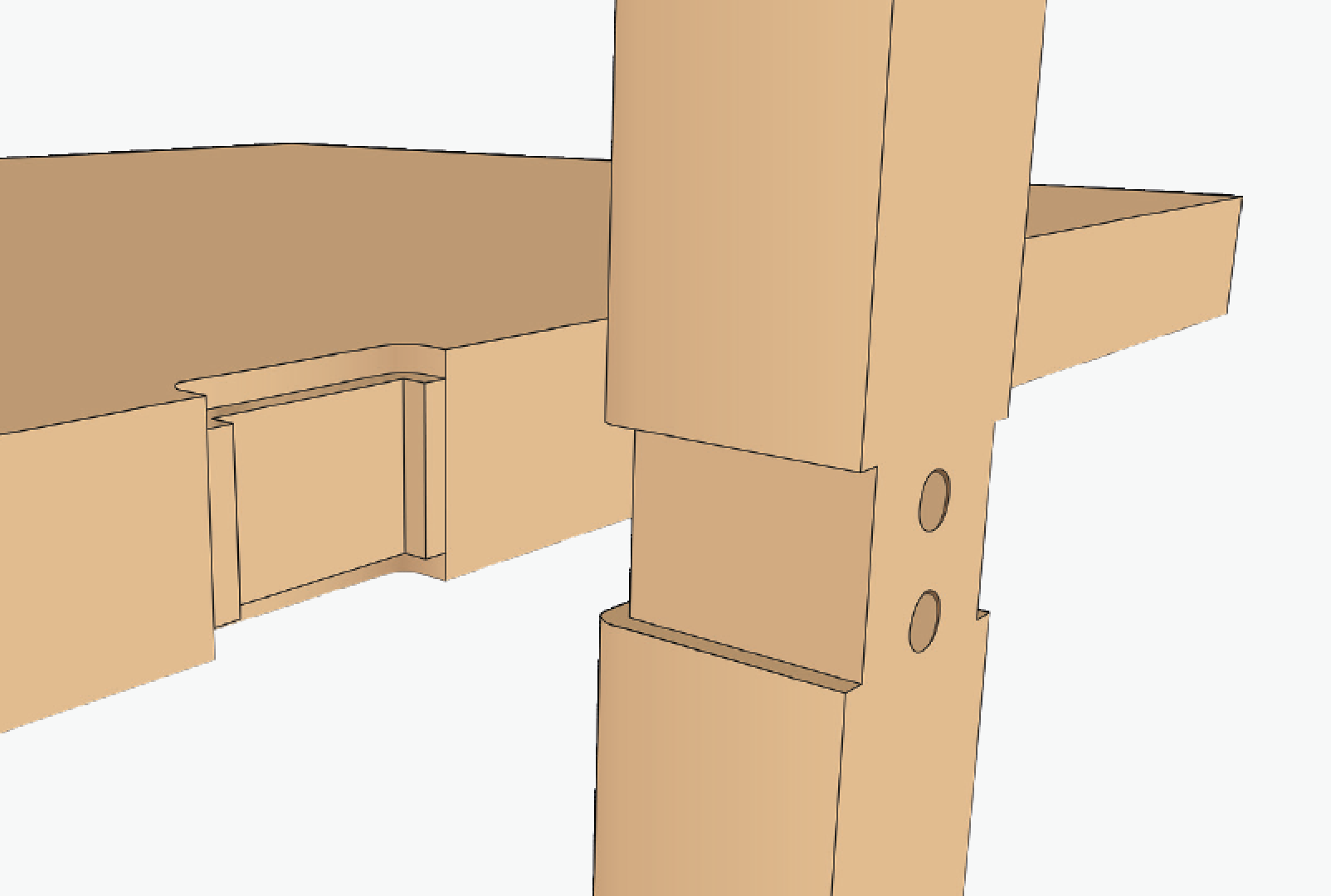

| Mortise and Tenon | Hide Glue or Polyurethane Glue | Hide glue offers excellent strength and reversibility; polyurethane provides exceptional water resistance and gap-filling capabilities. | Hide glue requires precise clamping and careful application; polyurethane can be difficult to clean up. |

| Dowel | Wood Glue (Aliphatic Resin) or Polyurethane Glue | Aliphatic resin glue offers good strength and ease of use; polyurethane provides superior water resistance. | Ensure proper dowel alignment for optimal strength; excess polyurethane needs careful removal. |

| Miter | Polyurethane Glue or Epoxy | Polyurethane’s gap-filling properties are crucial for miter joints; epoxy offers exceptional strength and water resistance. | Precise alignment is critical; epoxy requires precise mixing and a quick working time. |

| Lap | Hide Glue or PVA (Polyvinyl Acetate) Glue | Hide glue provides excellent strength and historical accuracy; PVA offers good strength and ease of cleanup. | Hide glue requires precise clamping; PVA might not be suitable for all wood types or extremely high-stress joints. |

Examples of Successful Chair Repairs Using Different Glue Types

A broken mortise and tenon joint in a Victorian-era armchair was successfully repaired using hide glue. The surfaces were meticulously cleaned, the joint carefully aligned, and clamped firmly for 24 hours. The hide glue’s reversibility is a key advantage, allowing for future adjustments if needed. This contrasts with a modern chair’s broken dowel joint, which was effectively repaired with polyurethane glue. Its gap-filling ability made it ideal for compensating for minor imperfections in the dowel holes. The cured glue provided exceptional water resistance, a vital consideration for a frequently used chair.

Glue Effectiveness on Different Wood Types

Hardwoods like oak and mahogany generally hold glue better than softwoods such as pine or balsa. The denser grain structure of hardwoods provides a more secure mechanical bond with the glue. However, even with hardwoods, the choice of glue remains crucial. For instance, while PVA glue might suffice for a simple repair on pine, a stronger adhesive like polyurethane or epoxy is preferable for high-stress joints in oak. A repair on a chair with a softwood frame might necessitate the use of a gap-filling glue like polyurethane to account for the wood’s porous nature, ensuring a stronger and more durable bond compared to using a standard wood glue alone.